Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

When you understand IQ/OQ/PQ deeply, you can:

- Plan validation efficiently (reduce rework and delays)

- Execute protocols with confidence

- Write strong validation documentation (IQ/OQ/PQ protocols and reports)

- Reduce FDA inspection risk (fewer 483 observations)

- Build a validation approach aligned with ISO 13485 and FD

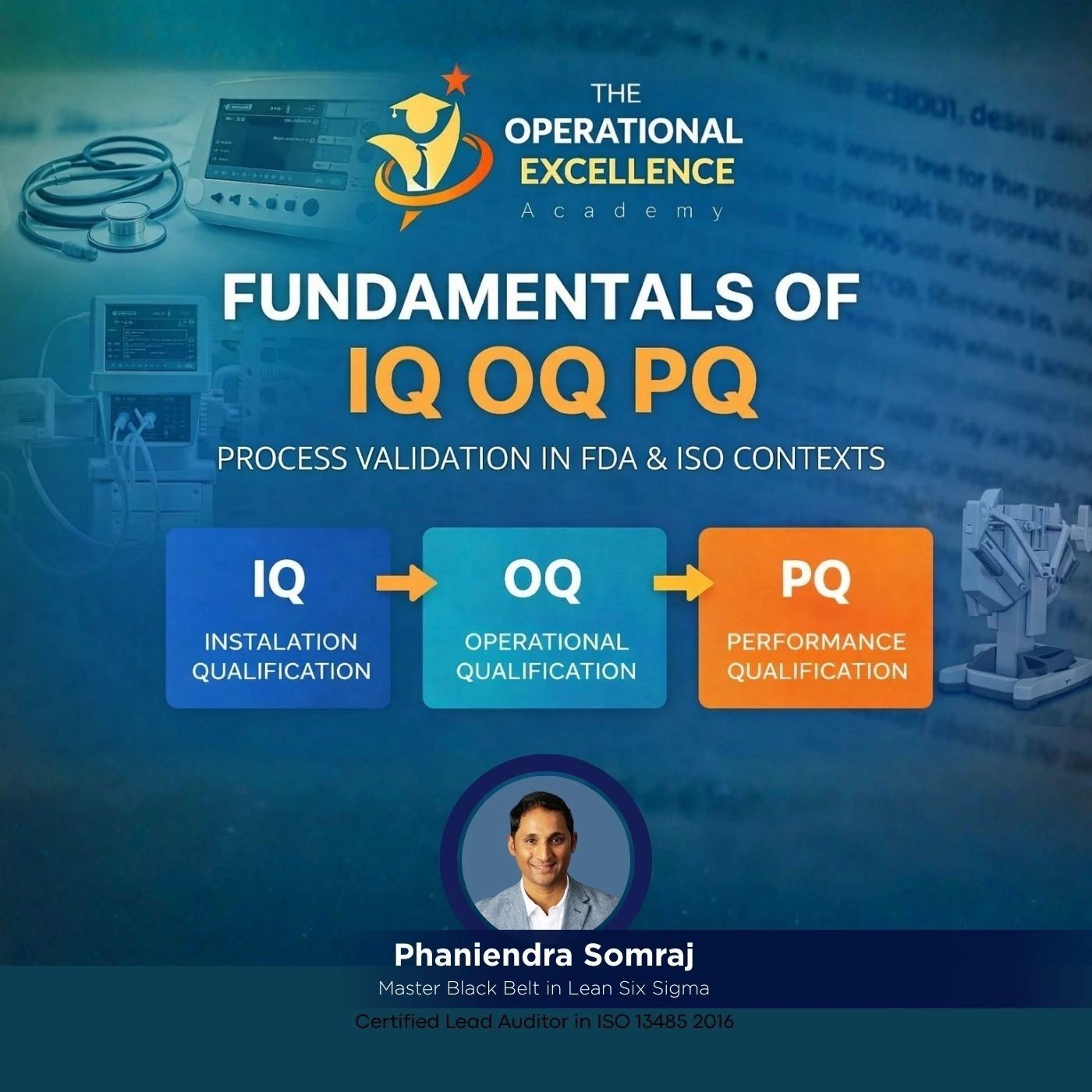

IQ OQ PQ Process Validation is a structured, evidence-based approach used in regulated industries especially medical devices, pharmaceuticals, and biotech—to prove that a manufacturing process is installed correctly, operates as intended, and consistently produces conforming product. The terms IQ (Installation Qualification), OQ (Operational Qualification), and PQ (Performance Qualification) are the most widely recognized components of the Process Validation lifecycle.

Process Validation is a core expectation in compliance frameworks like FDA 21 CFR Part 820 (Quality System Regulation / QSR) and ISO 13485:2016. It is required when the product output cannot be fully verified by inspection and test alone, or when the risk of failure requires stronger controls. In practical terms, IQ/OQ/PQ helps ensure patient safety, product performance, regulatory compliance, and repeatable quality.

In regulated manufacturing, it is not enough to say, “The process works.” Regulators expect objective evidence that the process is:

This is why organizations build a documented Process Validation program that aligns to:

Installation Qualification (IQ) verifies and documents that equipment, utilities, software (if applicable), and supporting systems are installed correctly according to approved specifications and manufacturer requirements.

Key IQ concepts

Installation Qualification (IQ) verifies and documents that equipment, utilities, software (if applicable), and supporting systems are installed correctly according to approved specifications and manufacturer requirements.

Key IQ concepts

Why IQ matters: If equipment is installed incorrectly, everything downstream (OQ and PQ) is built on a weak foundation.

Operational Qualification (OQ) verifies and documents that the process and equipment operate as intended across defined operating ranges. OQ typically includes testing of critical process parameters, alarms, interlocks, and controls—often including worst-case or boundary conditions.

Key OQ concepts

Operational Qualification (OQ) verifies and documents that the process and equipment operate as intended across defined operating ranges. OQ typically includes testing of critical process parameters, alarms, interlocks, and controls—often including worst-case or boundary conditions.

Key OQ concepts

Why OQ matters: OQ builds confidence that the process can be controlled and will perform reliably before you run “real production” PQ lots.

Performance Qualification (PQ) demonstrates that the process, when run by trained operators under normal production conditions using approved materials and procedures, can consistently produce product that meets all requirements. PQ is often executed using production-scale runs and focuses heavily on CTQs, product testing, and process co

Performance Qualification (PQ) demonstrates that the process, when run by trained operators under normal production conditions using approved materials and procedures, can consistently produce product that meets all requirements. PQ is often executed using production-scale runs and focuses heavily on CTQs, product testing, and process consistency.

Key PQ concepts

Why PQ matters: PQ is the proof point that the process is truly ready for routine production and can repeatedly meet specs in the real world.

A strong IQ/OQ/PQ program uses measurement and data tools to make validation defensible:

Copyright © 2025 The Operational Excellence Academy LLC - All Rights Reserved.